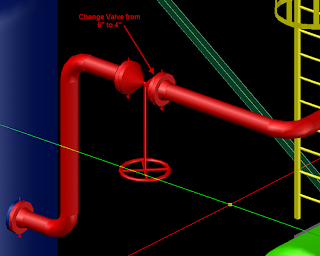

Select the valve, RMC on the valve and select Properties to see the size value.

◾Check in and out drawings

◾Utilize a horizontal workshare environment with multiple locations utilizing Vault Professional and AVFS (Autodesk Vault File Server)

◾Work locally from your Vault Workspace so you do not have to rely on poor network speeds when saving large models

◾Revision control

◾Permission control

This post is for CAD Managers for Plant 3D! I found a great decompiler for Python the other day. It is called Easy Python Decompiler and i found it on SourceForge. If you want to get into the Variants.ZIP file and see how all of these 3D solids in Plant are created and attempt to create your own, try it out!

You can download it here: https://sourceforge.net/projects/easypythondecompiler/files/bin/

You have created your project(s) and have been working for months or years in Plant 3D. The IT director comes in and says, "We are going to Vault Professional!" As a designer, you may be thinking sarcastically, "Oh great, something else to learn..." or you may be thinking, "We need something like this to help secure our projects and make horizontal workshare a real possibility!" You would be right on both thoughts. There are many advantages to making the move to Vault Professional in regards to AutoCAD Plant 3D, and we can help you explore those benefits. But you more than likely will have several projects you are already working on that will need to be moved to this new Vault. It is really an easy task and here are the steps.

In Plant 3D, open the project you want to convert. Do not open any of the drawings. From the command line, type in PLANTPROJECTTOVAULT. You will see the following dialog box asking you to enter in Vault and SQL information.

After selecting "Start" you will see the following dialog box indicating the process is underway. Just sit back a few minutes and let it run.

Once completed, you will be able to check in and out drawings from the project with the appropriate credentials set up in Vault. If you are curious about how Vault and Plant 3D work together, please do not hesitate to contact us for a discovery call. There is an explicit methodology of working with Plant 3D and Vault concurrently so be sure to reach out to us.

From time to time, you will come across a pipe route that just stumps you. This one came up today with a user and this was the solution to the route. If you know a better way, please comment and let us know and make us all better pipe designers

The scenario was two vertical pipes coming off of a tank. One pipe would turn right at a higher elevation than the second pipe. The second pipe would turn at 45 degrees and tee into the bottom of the first pipe's horizontal run.

Hopefully you can visualize the route from the images above. Here are the steps using some constructions lines, the TRIM command and LINE-TO-PIPE.

1. Erase the horizontal pipe on the higher elevation run.

2. Draw 2 construction lines: 1 replacing the horizontal pipe you just erased and 1 at 45 degrees horizontal off of the elbow. Make sure the line crosses over the 1st construction line in the plan view.

3. Once drawn, you will want to TRIM the 2nd line using the TRIM command. However, this is not a standard trim in that you will trim based on PROJECTed geometry so the syntax will look like this:

4. Now just draw a new LINE from the endpoint of the trimmed LINE and perpendicular to the 1st LINE:

5. Lastly, a LINE TO PIPE command from the Ribbon (PLANTCONVERTLINETOPIPE) will convert those LINEs to Pipe by selecting them with a crossing window or selecting them one at a time...

and your complex pipe route is complete! Again, if you know of a better way, comment and make us all smarter!

More complex routing to come! I will also be teaching this and other "Tricks of the Trade" at Autodesk University this year!

Look it up and sign up - PT21675 Plant 3D: Tricks of the Trade 2.0

http://au.autodesk.com/

Here is the scenario:

Horizontal route needs to turn down vertically and then needs to turn horizontally to lie across steel.

To route this pipe, you will want to continue the pipe run by selecting the pipe and then the + at the

end of it. You will pull down seeing an elbow in the route.

You will need to set the routing line to BOP. You will find this in the ribbon (Home tab, Routing &

Elevation panel)

Select the Steel member’s top edge and notice that the pipe will not travel past the steel when you

pull in that direction. Make sure your Ortho (F8) is turned on. You will also notice that the red line

should be on the BOP and not on the COP.

Change your PLANE (compass) to a horizontal configuration to get the pipe to lie across the steel.

If it is not changed, the COP will still be on the TOS. When you pull in the direction of the steel, you

will see the pipe lying on the TOS.

Lastly, pick or enter the length of the pipe you desire and see the results. Your BOP should be the

same as the TOS and you were able to do this without knowing the TOS elevation

More complex routing to come! I will also be teaching this and other "Tricks of the Trade" at

Autodesk University this year!

Look it up and sign up - PT21675 Plant 3D: Tricks of the Trade 2.0

http://au.autodesk.com/

This year Autodesk University has been moved to the week before Thanksgiving instead of the week after. Mark your calendars for the November 15-17!

Registration for AU opened August 17! You will want to register early to ensure that the classes you want are not filled up. As you register make sure you check out the class I will be teaching. As you can see, as of today, it is down to 23 seats remaining so sign up before they are all gone!

See you in Vegas!

The little icon that probably does not get used very often is actually a very nice tool for automatically cutting back members to include a gap if required. See the image below of the structural members. They were placed on a grid on center, which will require some clean up. The grid has been turned off for clarity.

We need to trim the members back and to do this quickly, we will use this tool as seen in the next image.

So as the instructions indicate, this tool will cut multiple members back to the edge of a member that is placed on endpoints of the adjacent members. After selecting the command, it will prompt you to enter in a "gap", which can be just zero or can be a gap that you specify. This will leave a gap between the end of the member and the face of the cutting member.

Select the members you wish to cut back. In the example below, I just used a crossing window to select them all at once.

After selecting the members you need to cut back, hit ENTER and see the work done for you! This is much better than doing one at a time.

Experiment with this tool to see how you can add gaps in the cut and look for circumstances that it does not work for, because there are some of those too.

You can now view the class "AutoCAD Plant 3D: Tricks of the Trade 2" from this year's Autodesk University. You will learn such things as...

Click here >> AutoCAD Plant 3D: Tricks of the Trade 2

Have you ever experienced the issue of your vertical pipe in a sloped socketweld pipe run not being truly vertical? This screencast will help!

If you have been in the loop with AutoCAD Plant 3D over the past year, you have probably heard of Project Calgary which was the beta of Collaboration of Plant 3D Projects in the Cloud. Why is this an important feature for AutoCAD Plant 3D? It centralizes your project for multiple sites and still allows you to work locally as if you were on Vault. Look at it like using Vault in the Cloud, because that is precisely what it is!

How does this work? Today, I created a new project, local using SQLite. I called it "Cloud Project Demo." I did not reference any other projects. I just wanted to start from ground zero and go from there. I created one P&ID drawing in the project called 1001.DWG. Upon creating the first DWG, I was able to go to the new "Collaboration" tab in the ribbon and selected "SHARE PROJECT" after which I was shown the following dialog box:

Pretty simple so far! After selecting "GET STARTED!" you will be prompted to close any DWG you have open in the project if you left one or more open and then you will be prompted to select a BIM 360 Team project folder you have already created. If you haven't created one, you will need to do that first. By the way, the ribbon option to "Share Project" will not highlight unless you have a drawing open. Also, I have found that if you upload to Fusion 360, the projects will not be seen by your team. Make sure it is a BIM 360 Team Hub.

After selecting the folder, sit back a minute or 2 and let the project upload to the cloud...

Next, you need to determine who is going to work on this project with you. It is collaboration, after all.

After the "INVITE MY TEAM" takes you to the site, invite your Project team by entering in their email address.

Back in AutoCAD Plant 3D 2018, you can go to the Project Manager, right-click on a drawing and see the new "Project Collaboration" commands, such as Check Out.

If you have used AutoCAD Plant 3D with Vault in the past few releases, you will quickly start to see some of the familiar icons for files checked out to you and files checked out by others. You can even set it up to notify you by email when DWGs have been updated by others.

Give it a whirl! This is good stuff and highly requested technology! Kudos to the Autodesk Plant Development Team!